Planar Versus Conventional Transformer

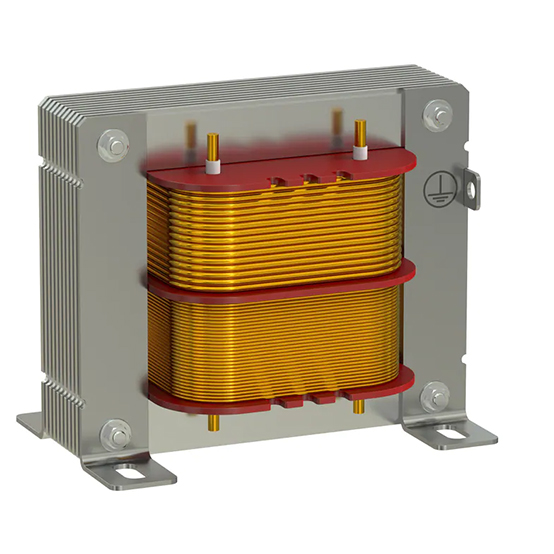

Transformer technology, both conventional and plane, has been around for many years. Both types of transformers use the same rules to design. Understanding the differences between the two is essential when deciding on your design.

This article discusses the key differences between planar and conventional transformers. We will cover various aspects such as design, materials used, costs, efficiency, and safety. By understanding these factors; you can decide which type of transformer best suits your application needs.

Planar and Conventional Transformer Differences

Planar and conventional transformers differ mainly in design, size, materials, cost, efficiency, and safety. Here's an overview of their main differences.

Height

Planar transformers are generally much lower in height than conventional transformers. This is because the windings in planar transformers are printed on a multi-layer PCB, or using flat copper windings, instead of wrapping wire around a core. This makes them ideal for applications that require a low-profile design. On the other hand, conventional transformers require bulky cores and multiple layers of insulation to function properly, resulting in a larger size.

Power Density

Planar magnetic designs have higher power densities than conventional transformers. This means you can provide higher power output in a much smaller package. For example, Payton’s planar transformer offers up to three times more power density than conventional transformers.

Efficiency

Planar transformers tend to be more efficient than conventional transformers because there is less space for heat to build up. This can result in lower energy losses and improved performance. Payton’s planar transformers typically have a 98% efficiency without an increase in volume.

Resistance

Resistance is an important factor to consider when comparing planar and conventional transformers. Planar transformers are usually more resistant to heat since the windings are on a multi-layer PCB, which helps dissipate the heat more effectively than traditional cores used in conventional designs. This can help reduce energy losses and improve efficiency. On the other hand, conventional transformers tend to have higher resistance due to the multiple layers of insulation used in their design.

EMI

EMI is another key difference between planar and conventional transformers. Planar transformers are more resistant to EMI– its windings layout on the PCB helps reduce noise interference. On the other hand, conventional transformers can be more susceptible to EMI issues due to their bulky cores and insulation layers.

Heat Transfer

Heat transfer/thermal conduction is a crucial factor when comparing planar and conventional transformers. Planar transformers’ multi-layer PCB design helps dissipate the heat more effectively than traditional cores used in conventional transformers. Planar transformers have a shorter thermal path and lower rise in temperature. This can help reduce energy losses and improve efficiency. Additionally, you can achieve further heat dissipation by attaching the planar transformer to a chassis or heat sink.

Leakage

Inductance leakage is an important factor to consider when comparing planar and conventional transformers. Payton’s planar transformers have about a 0.2% leakage of primary inductance. Conventional transformers are more susceptible to leakage due to their bulky cores and insulation layers than planar units. Additionally, planar transformers often have additional shielding to reduce the potential for leakage.

Need Help Choosing a Transformer?

When choosing the right transformer for a given application, there are several factors to consider. Reliability, cost, power requirements, and environmental conditions are all important considerations when selecting the best transformer for your needs. Additionally, it is vital to consider the differences between planar and conventional transformers to decide which type is best suited for the job. For more specific details on technical differences, we can help. Planar transformers from Payton Group offer superior performance and reliability, making them an excellent choice for many applications.

If you need help selecting or designing a new planar transformer for your device, contact us today and let us help you find or make the perfect solution for your needs.